|

Using a Wood Lathe

Lesson 5 - Tool Process in Spindle Turning

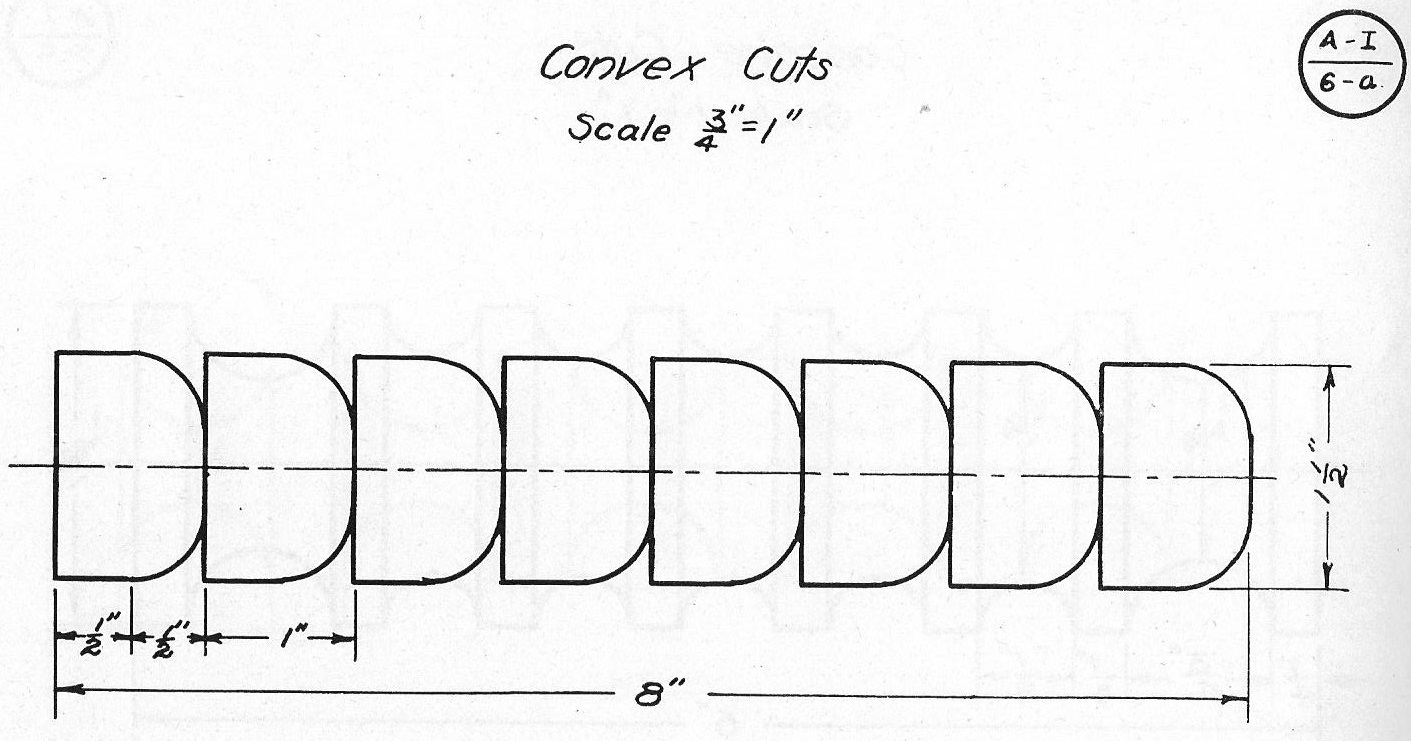

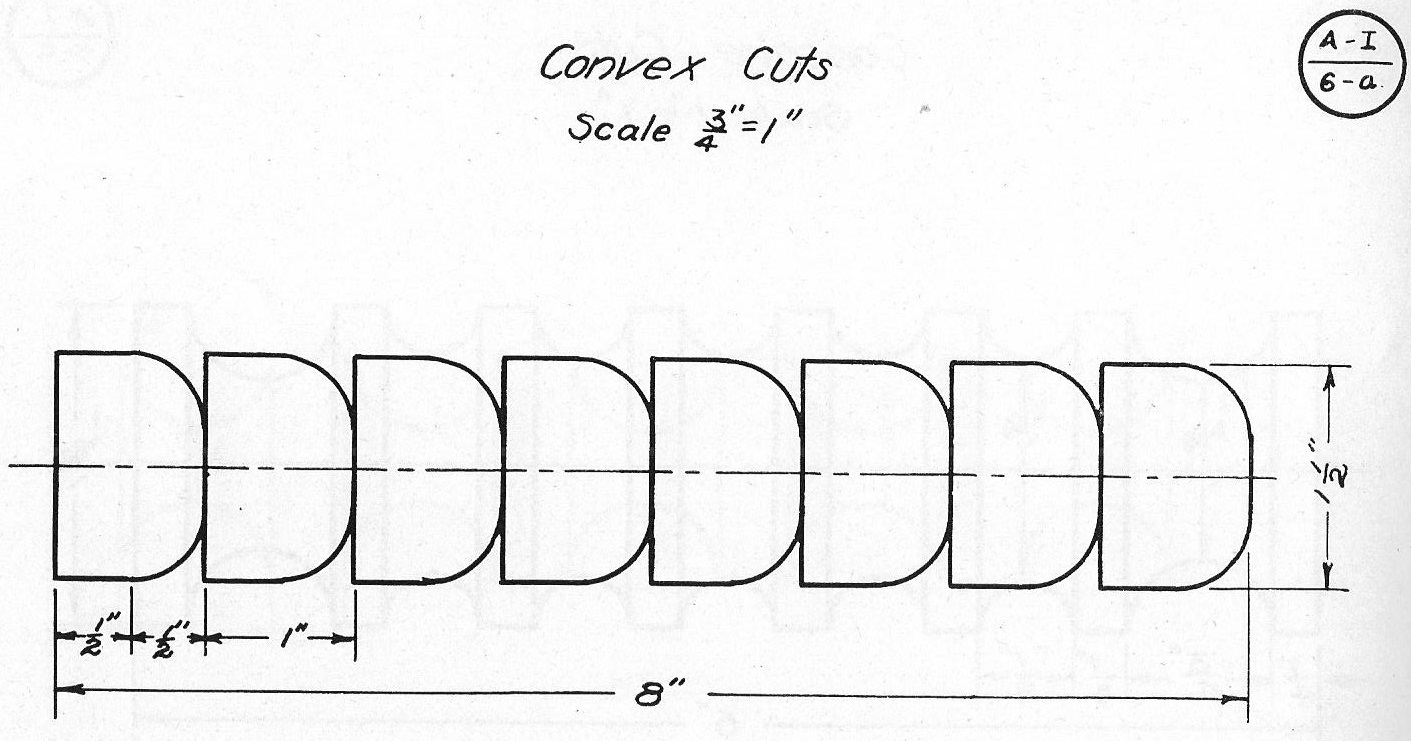

Exercise A-I-6-a. Convex Cuts |

The convex cut, or Bead as it is usually called, is generally considered the hardest cut to make.—The cut is made with the heel of a small skew chisel, usually the ¼” or ½”.

After the cylinder has been marked off, rough out all stock between the beads with a parting tool. The bae of the cuts is finished the same as described in Plate A-I-1-a, for shoulder cutting. With a sharp pencil mark the center of each bead to be made. This line is the starting point for all cutting.

Place the chisel on the rest, with the cutting edge above the cylinder and the lower grind tangent to it. Draw the chisel back and raise the handle to bring the heel of the chisel in Contact with the cylinder at the line indicating the center of the bead. The chisel is then moved to the right (if cutting the right side of the bead); at the same time the chisel is continually tipped to keep the lower grind tangent to the revolving cylinder and also to the bead at the point of contact. Fig. 13. This cut is continued until the bottom of the bead is reached. It is well in turning a series of beads to work the same side of all before reversing to the other side.

Note : - The same principles employed in this exercise are also used in working out long convex curves such as are found in chisel handles, mallet handles, etc. The only exception is that in most cases the point of contact need not be the heel of the chisel but higher up as in ordinary straight work. |

(Fig. 13) |

Exercise A-I-6-a

Exercise A-I-6-b

Exercise A-I-6-c

Exercise A-I-6-d

|

|