|

Duplication

Under the head of duplicate turning have been classified only such models as clearly indicate the necessity of making two or more articles to complete the model or set of articles desired. But it is not intended to convey the idea that other models may not be made in duplicate as in many cases it is very desirable and even preferable that they should be made that way. Whatever the problem may be the suggestions offered at this point may be applied effectively.

Whenever two or more models are to be made identically alike there are always two possibilities of inaccuracies that will render the work dissimilar: First, inaccurate ‘measuring both for length and points of new diameters and also on the new diameters themselves; second, a variation in the curved surfaces either on long convex or concave cuts.

The first difficulty can be overcome to a great extent by the use of a measuring stick. This stick should be made of any soft wood. It should be straight on one edge and about the thickness of an ordinary rule. On the straight edge lay off very carefully measurements for length, shoulders, beads, concaves and all points Where calipering for new diameters will be necessary. Insert at each point measured a small brad which has been sharpened at both ends, leaving the end protrude about 1/8”. Care should be taken that all brads protrude the same distance.

After the stock has been turned to the largest diameter, the stick is held in the position of the rule while measuring and the points are forced against the revolving cylinder, thus scoring it. This stick can be used as many times as the model is to be made and the measurements will always be the same.

To avoid dissimilar curves it is well to cut out a full sized template of the model to be made. This template can be made of any thin, stiff material, preferably light sheet iron. In some cases it will be necessary to make the template in several pieces in order to help facilitate the tool operations.

The use of this template will not only be a help to getting all curved surfaces the same, but will also check up on the various new diameters on the model. The cylinder should never be in motion while the template is being used.

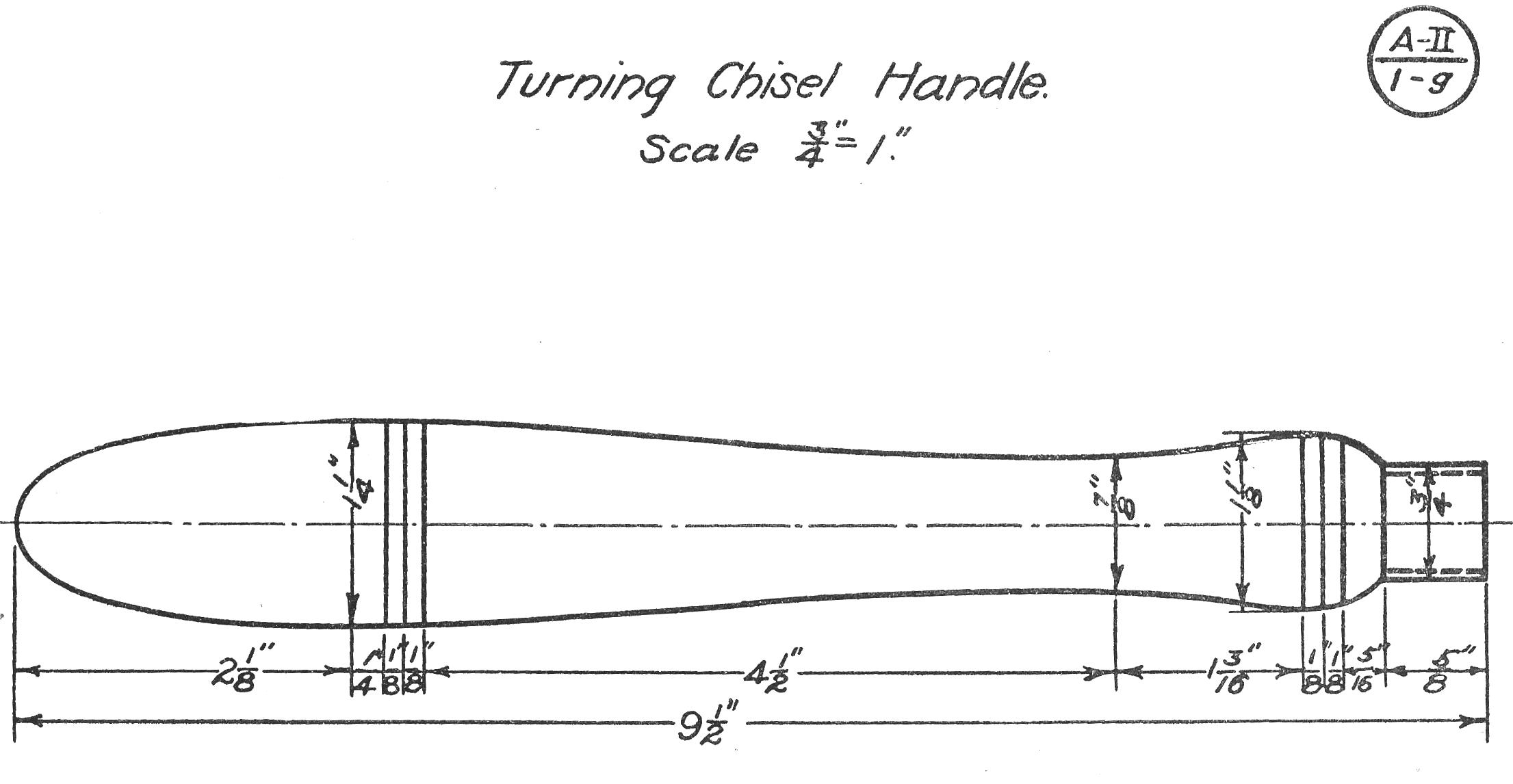

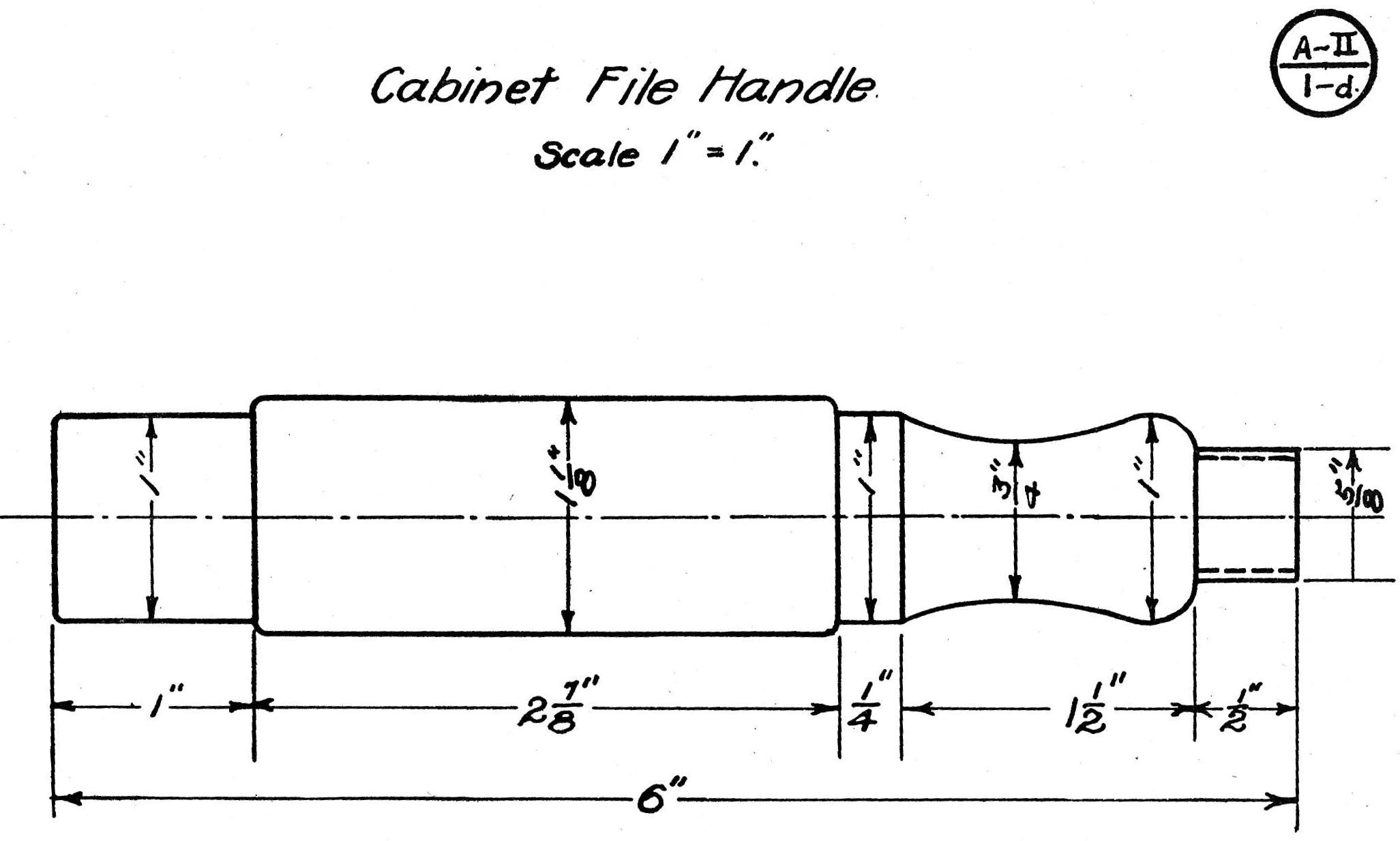

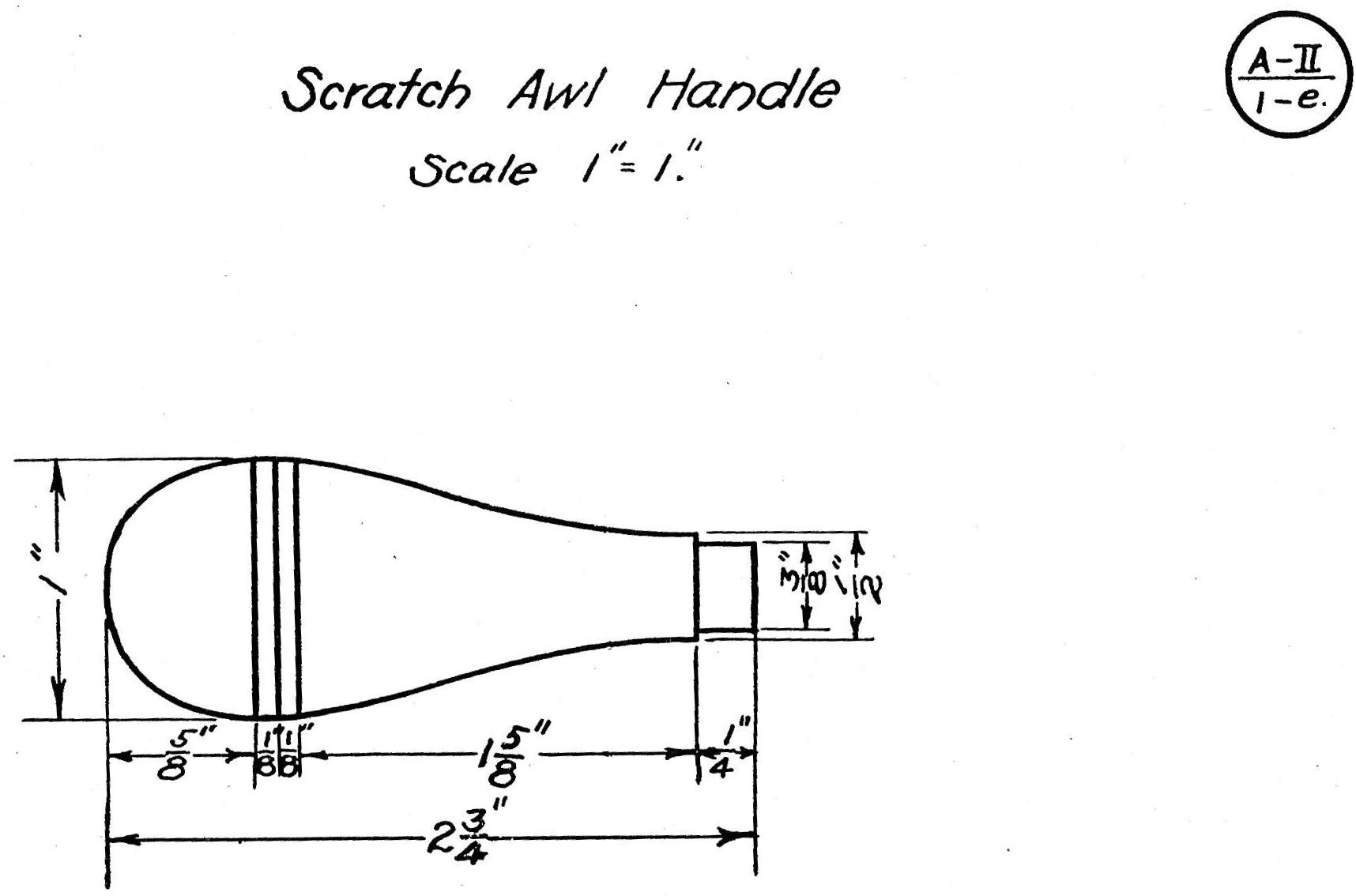

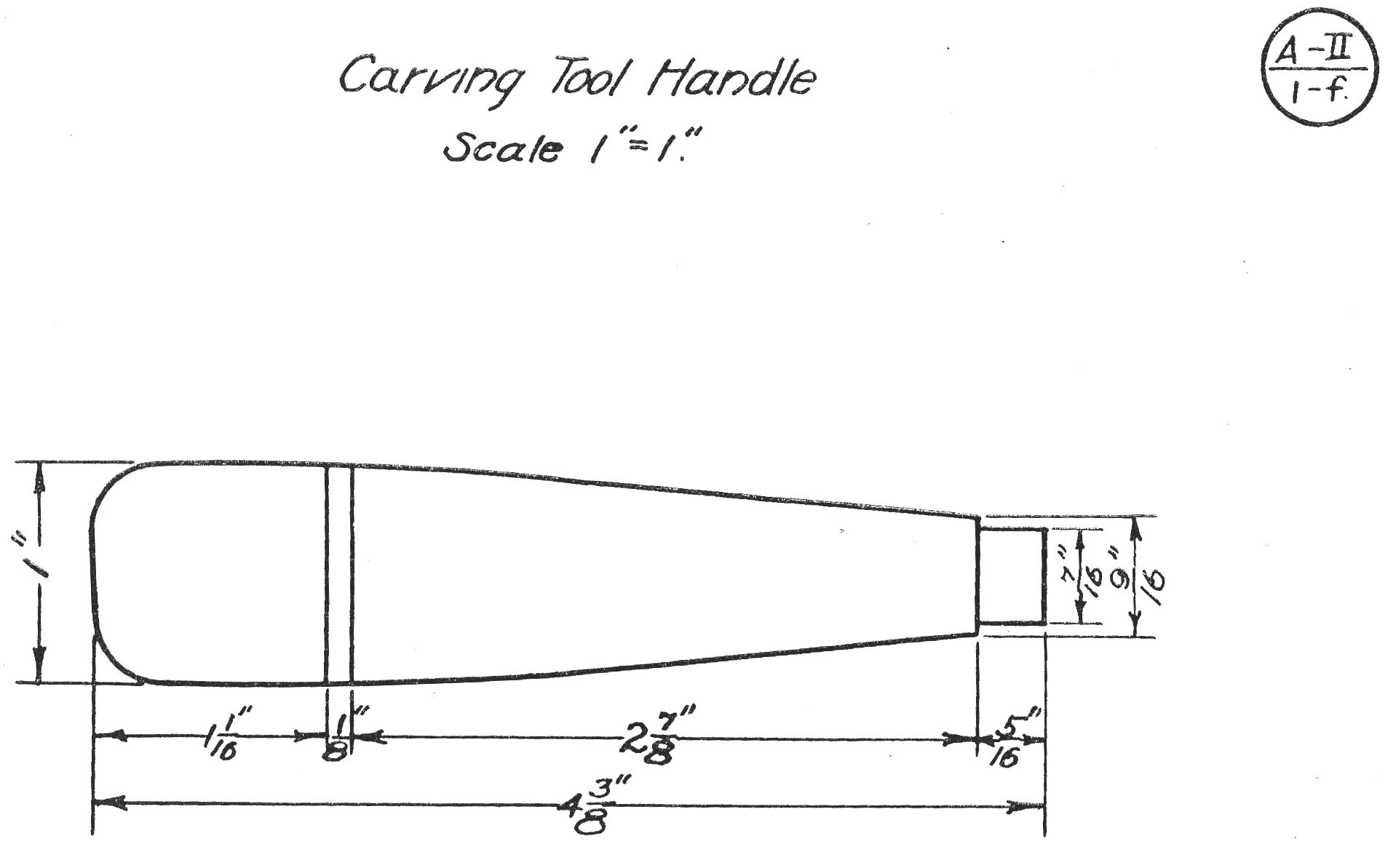

Here are numerous projects to practice duplication.

|