| TheWoodcrafter.net |

Copyright © 2004. |

| My Basic Projects |

| The Retro Section |

| Jr. Woodcrafter |

| My Work |

| Detailed Plans |

| About |

| Lathe Work |

| Safety |

| Hints |

| Pic Gallery |

| Links |

| Search |

| Home |

| Birdhouses |

| Guest Book |

| Contact Us |

|

|

||||||||

|

Here is the original article from the

January - February 1957 Deltagram

ROCKWELL MANUFACTURING COMPANY - A DELTACRAFT PULICATION

Bird Feeding Station

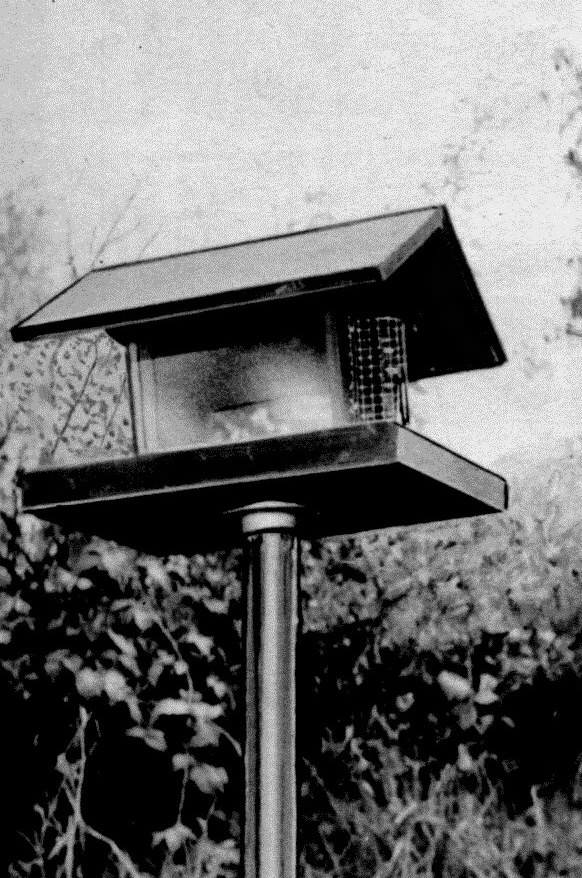

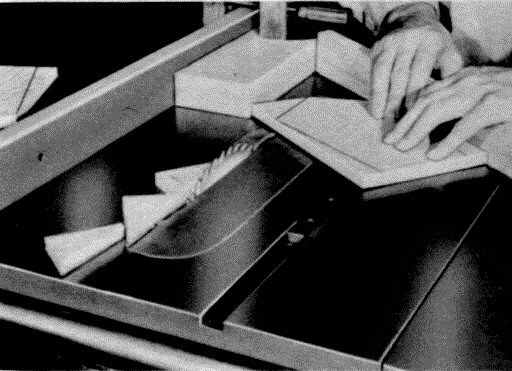

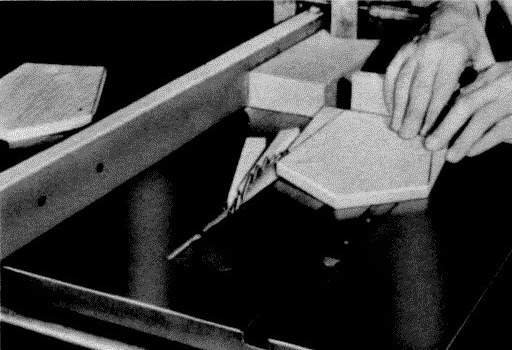

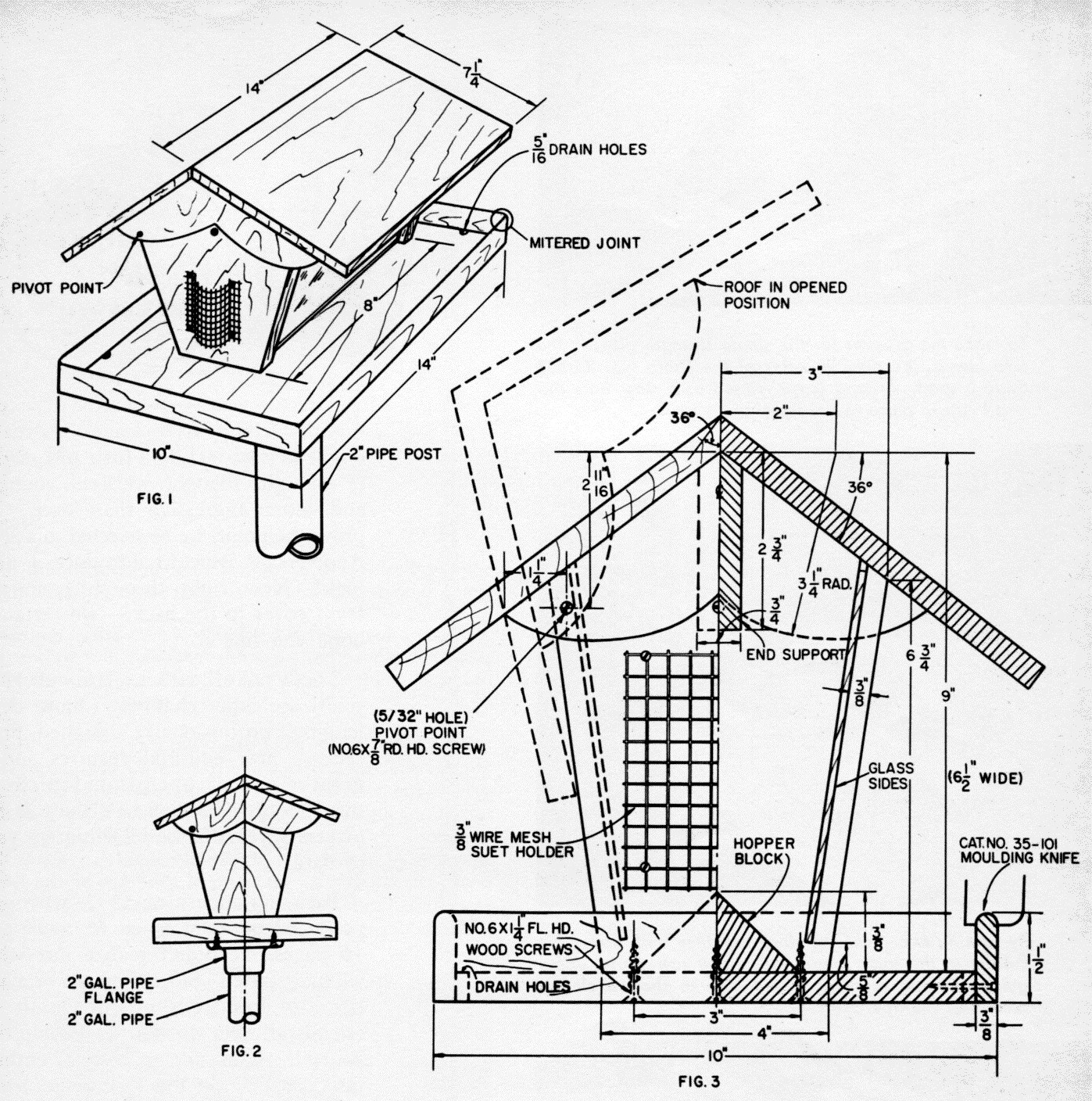

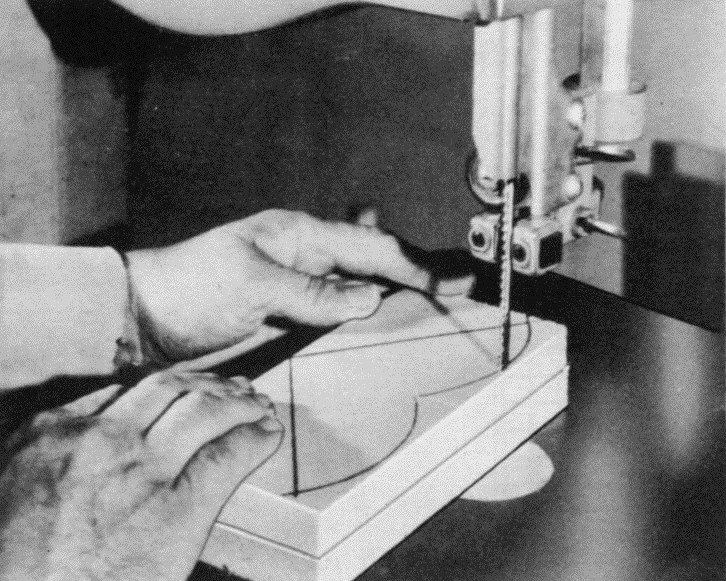

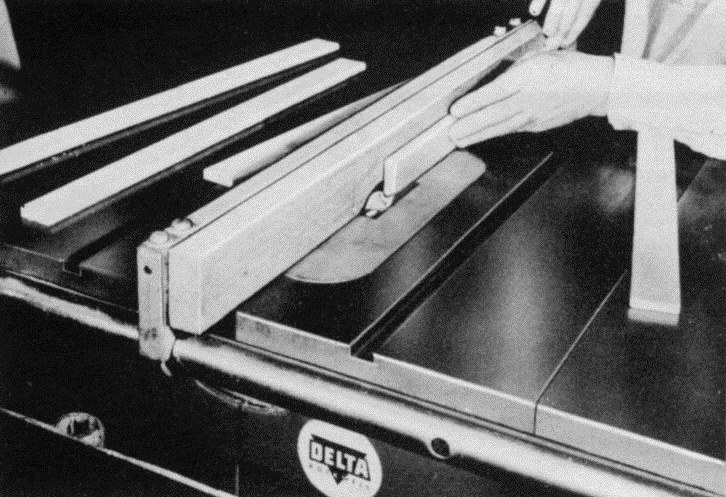

| The top pivots away for quick filling of this easy-to-build bird feed station. The glass sides let you see just how much feed is left. Wire suet containers can be added to complete the station and keep birds coming back the year around. All stock is ½ inch thick except roof trim and ridge which are ¾ inch thick and the 3/8 inch thick tray ends. Best material for this feeder is cypress, redwood, cedar or pine. Cut two pieces for the feeder sides 6 inches wide by 9 inches long. Make the two side angle cuts first by setting the miter gage at 54° (see Photo #2). The roof angle cuts are made by setting the miter gage at 82° (see Photo #3). Refer to drawing for cutting dimensions. Stop grooves for single strength glass fronts are cut on the circular saw using one of the outside dado cutters (see Photo #4). Note that these grooves are cut 5/8 inches from the bottom of the sides; this is to allow for the feed opening. By making the glass 6½ inches wide, a slight opening remains at the top to circulate air through the feed storage compartment. Screw fasten the ¾ inch thick ridge or end support as well as the hopper block to the sides, see drawing for details on these pieces. |

The roof boards are cut 7¼ x 14 inches with a bevel cut on one long edge at 56°. Side eaves are made of ¾ inch thick stock and fastened to the roof boards with 1½ inch finishing nails and waterproof glue. Before assembling the eaves to the roof, drill a 5/32 inch hole on one side of each eave, this is used as a pivot point, see drawing (Fig. #3). Top edge of base sides is rounded with the Delta No. 35- 101 moulding cutters mounted on the No. 265 moulding cutter head. The pieces are fitted with mitered joints which are then nailed and glued as shown in the drawing. Note the 5/16 inch drain holes in the very edge of the base board. These should be spaced about three inches apart. The base is screw fastened to the feed storage compartment with No. 6 x 1¼ inch ?at head wood screws, brass preferred. Finish the entire feeder with a coat of stain made by mixing one part of roofing tar and one part of turpentine. When feeder is dry, mount a 1½ or two inch pipe flange (Fig. 2) and screw onto a six foot length of pipe. The feeder should be about 49 inches from the ground for easy filling of feed. 1/4 inch wire mesh can be screw fastened on each end to hold pieces of suet. |

Right-click here to download the drawing as an Adobe Acrobat (pdf) file.

* * * * Click on the drawings above to download a higher resolution picture. * * * *

*********** WARNING***********

Read my page on safety before building this item.