| TheWoodcrafter.net |

Copyright © 2004. |

| My Basic Projects |

| The Retro Section |

| Jr. Woodcrafter |

| My Work |

| Detailed Plans |

| About |

| Lathe Work |

| Safety |

| Hints |

| Pic Gallery |

| Links |

| Search |

| Home |

| Birdhouses |

| Guest Book |

| Contact Us |

|

|

||||||||

|

Build this

Metal & Plastic Candleholder set

Here is the original article straight

from

Book No. 4514, PRACTICAL DELTA PROJECTS

NEW & NOVEL THINGS TO MAKE,

BOOK 14

DELTA MFG. DIVISION

|

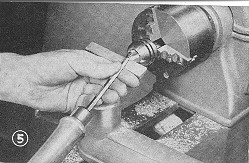

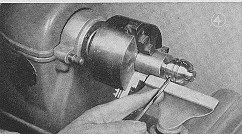

HERE is an attractive pair of

candle sticks which you can turn with the new

carbide tipped turning chisels. The finished

products are shown in Photograph No. 1. The

plastic base is turned from 1/4" clear

Plexiglas, while the cup itself is turned from

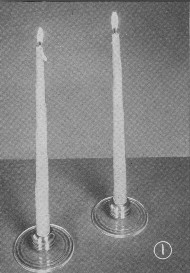

1-1/2" free turning brass rod. Photograph

No. 2 shows the brass rod chucked in the lathe,

using the 3-jaw self-centering chuck. The bottom

of the candle cup is turned first. (See full-size

drawing on the following page) After turning this

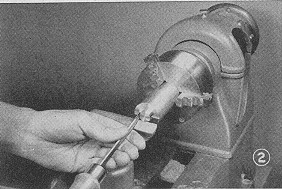

bottom step, the bowl itself is turned round as

shown in Photograph No. 3. The round nose carbide

tipped turning chisel is used for this operation.

This chisel is used free-hand as described in the

announcement enclosed with your last Deltagram.

The tip of the chisel is pivoted or rolled back

and forth to get a good, clean cutting action. |

||

|

|||

| * * * * Click on the picture above to download a higher resolution picture. * * * * |

*********** WARNING***********

Read my page on safety

before building this item.