|

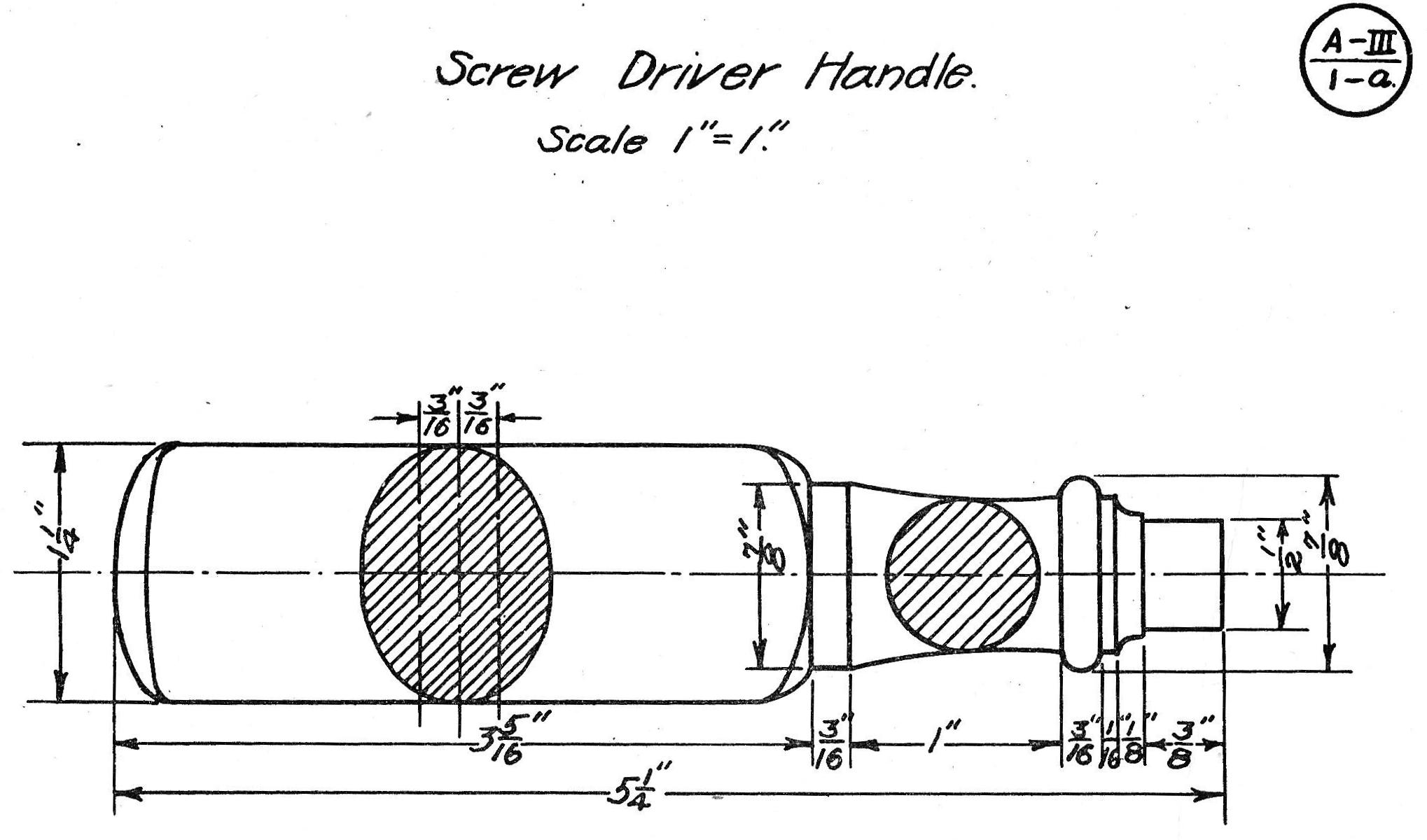

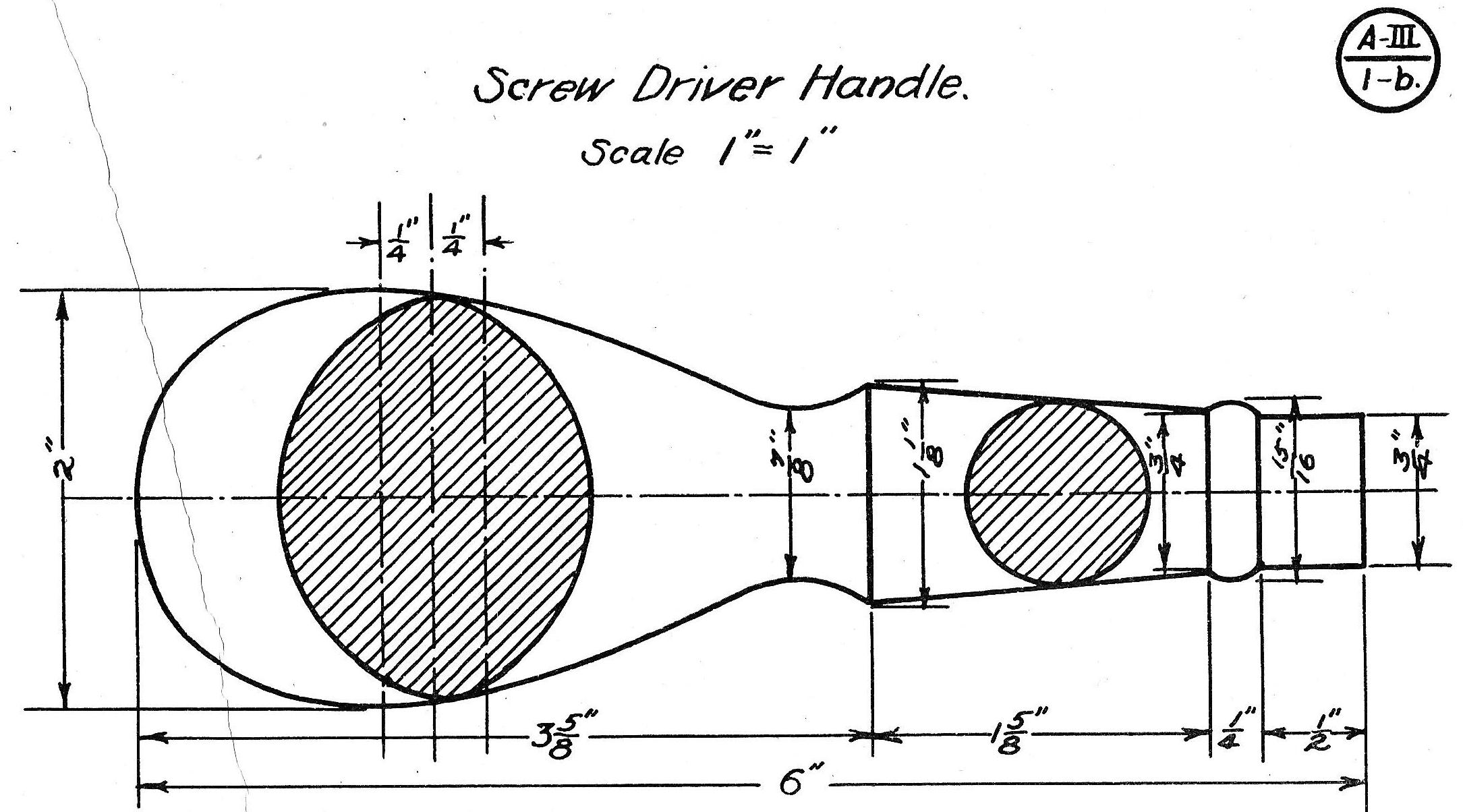

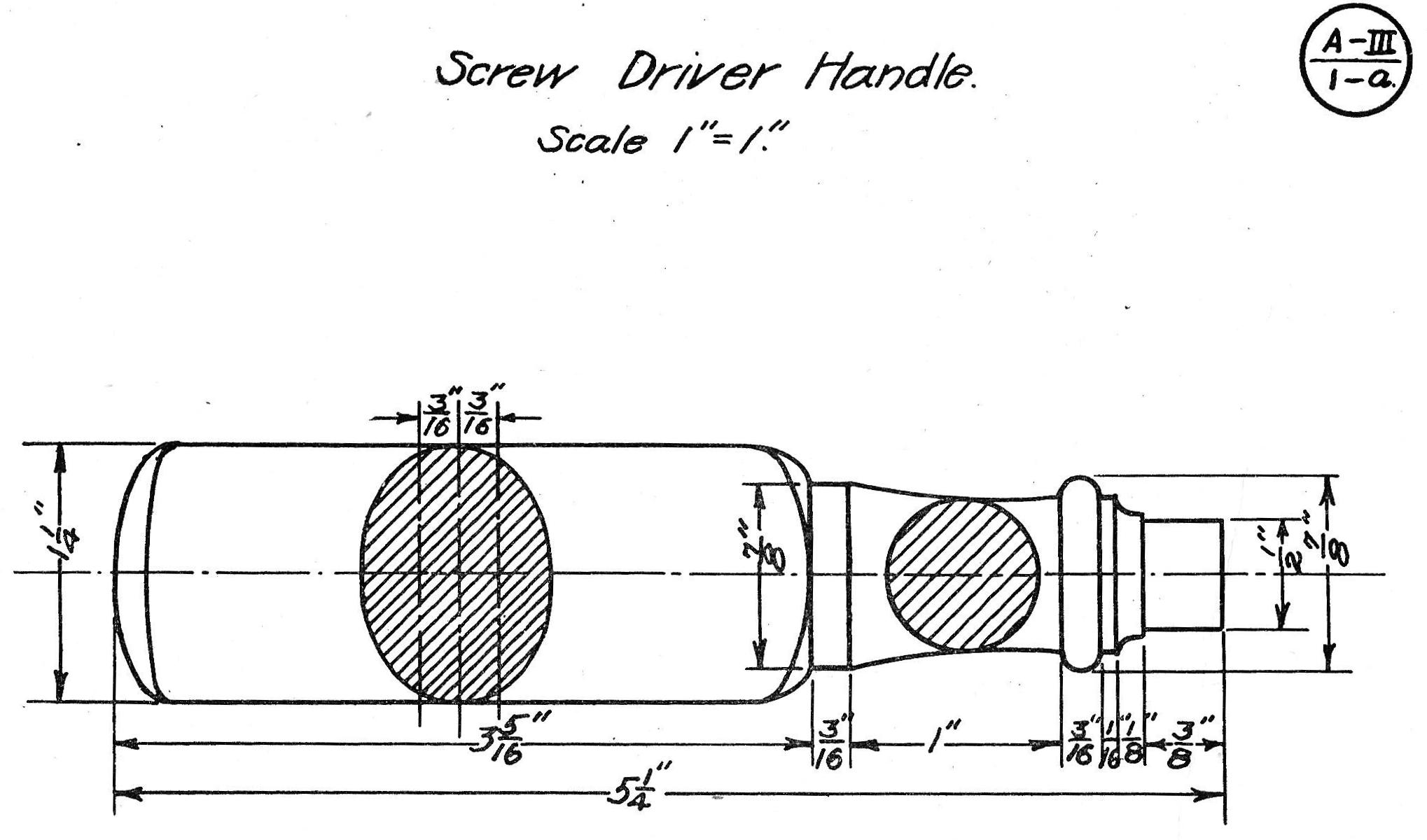

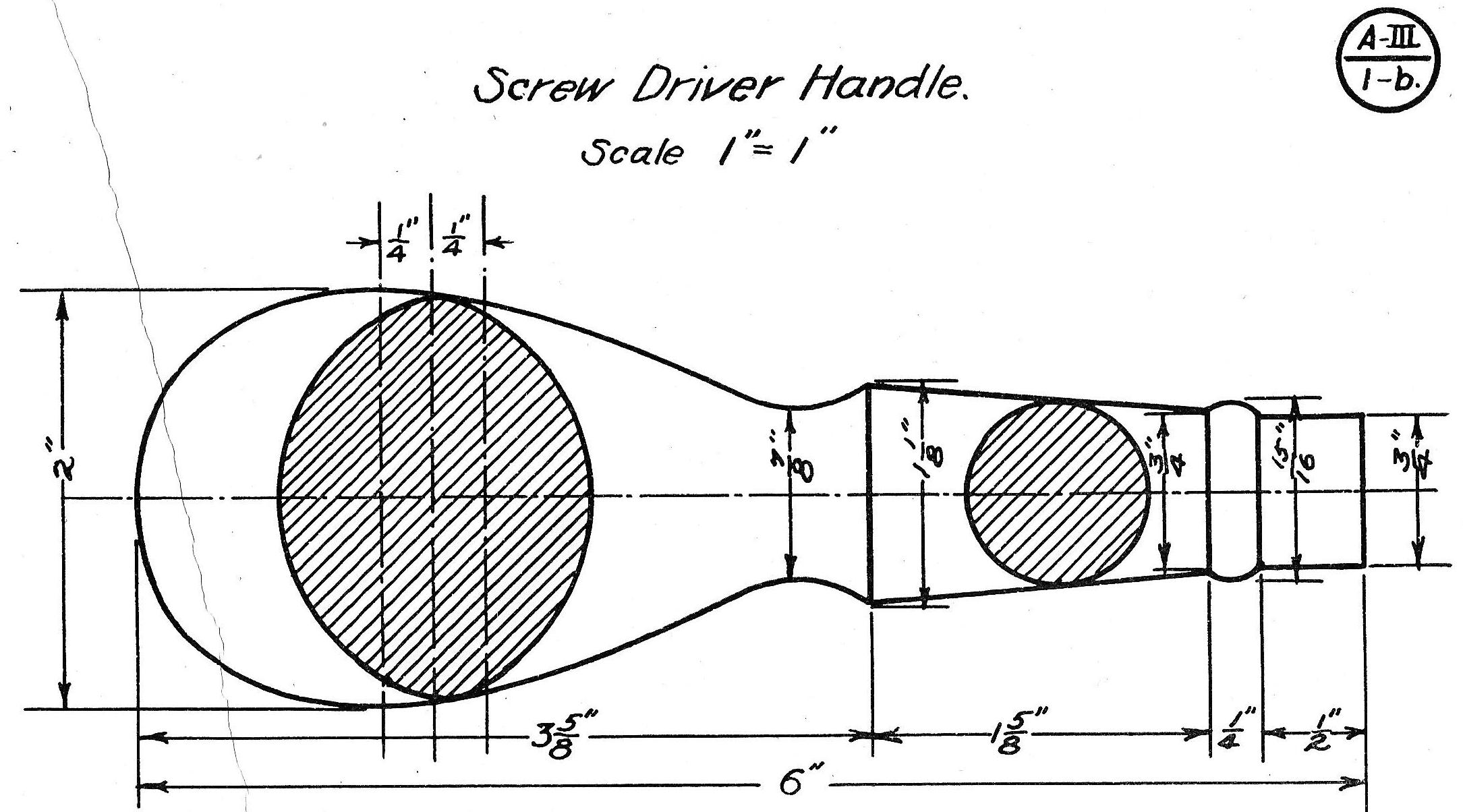

Screw Driver Handles

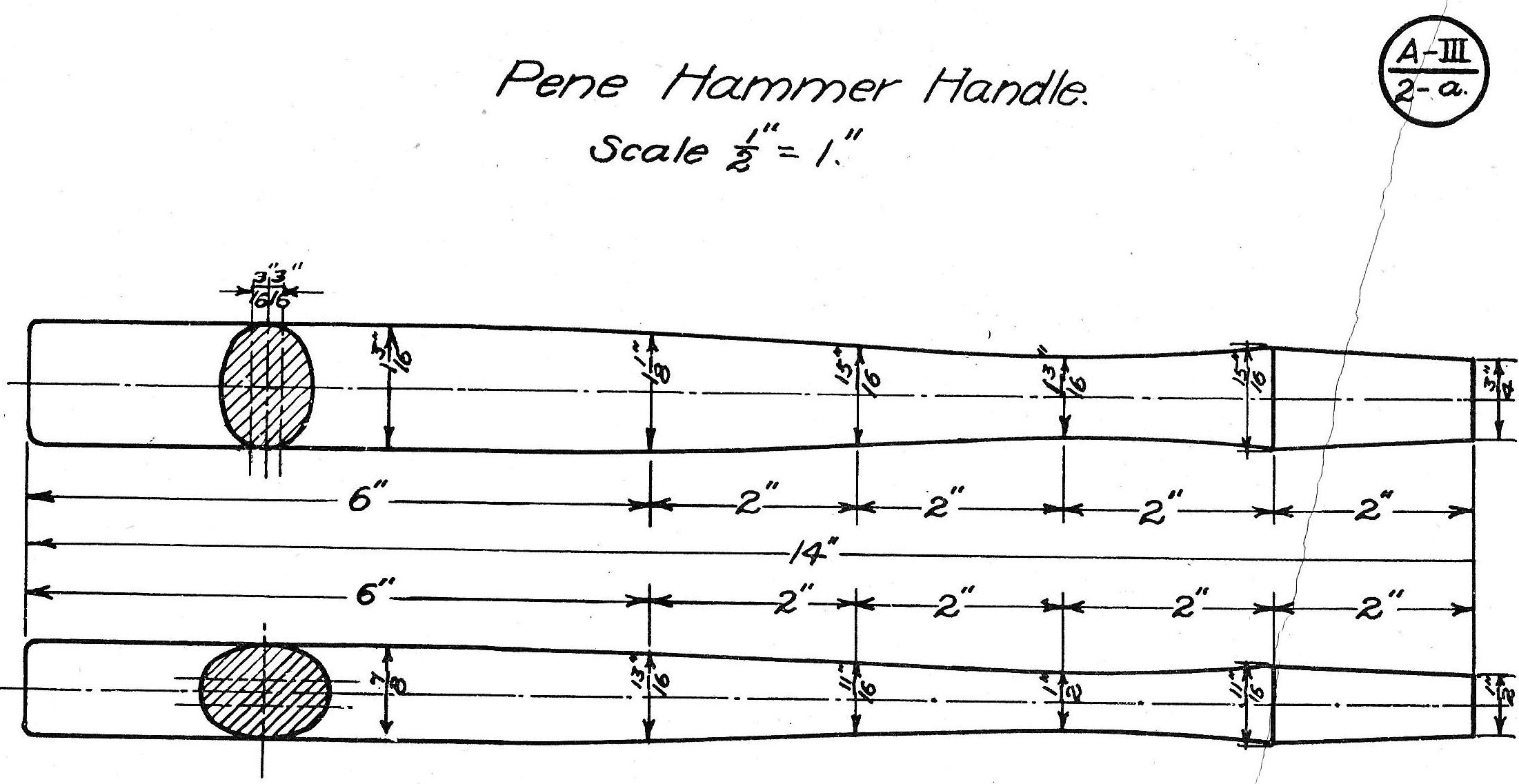

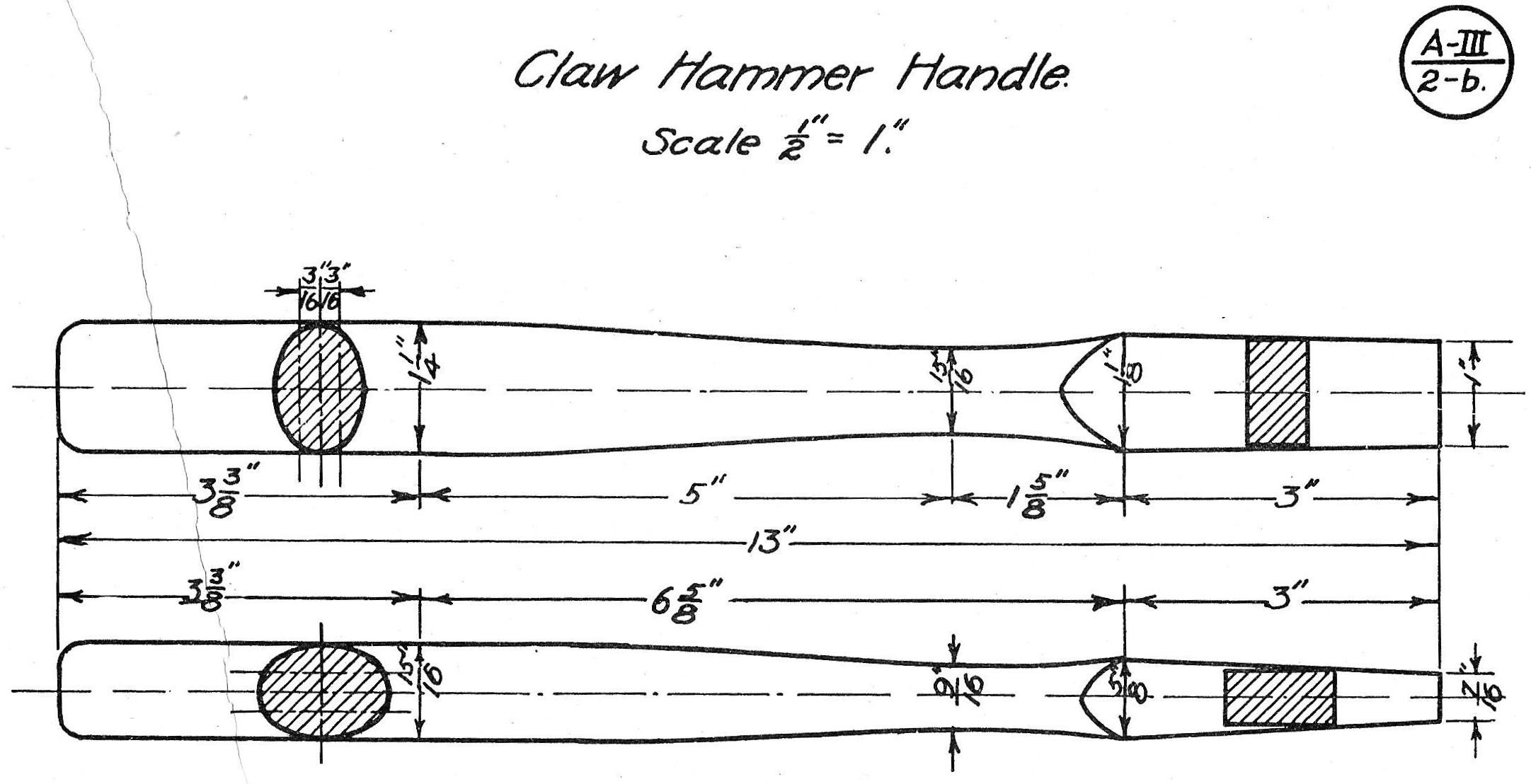

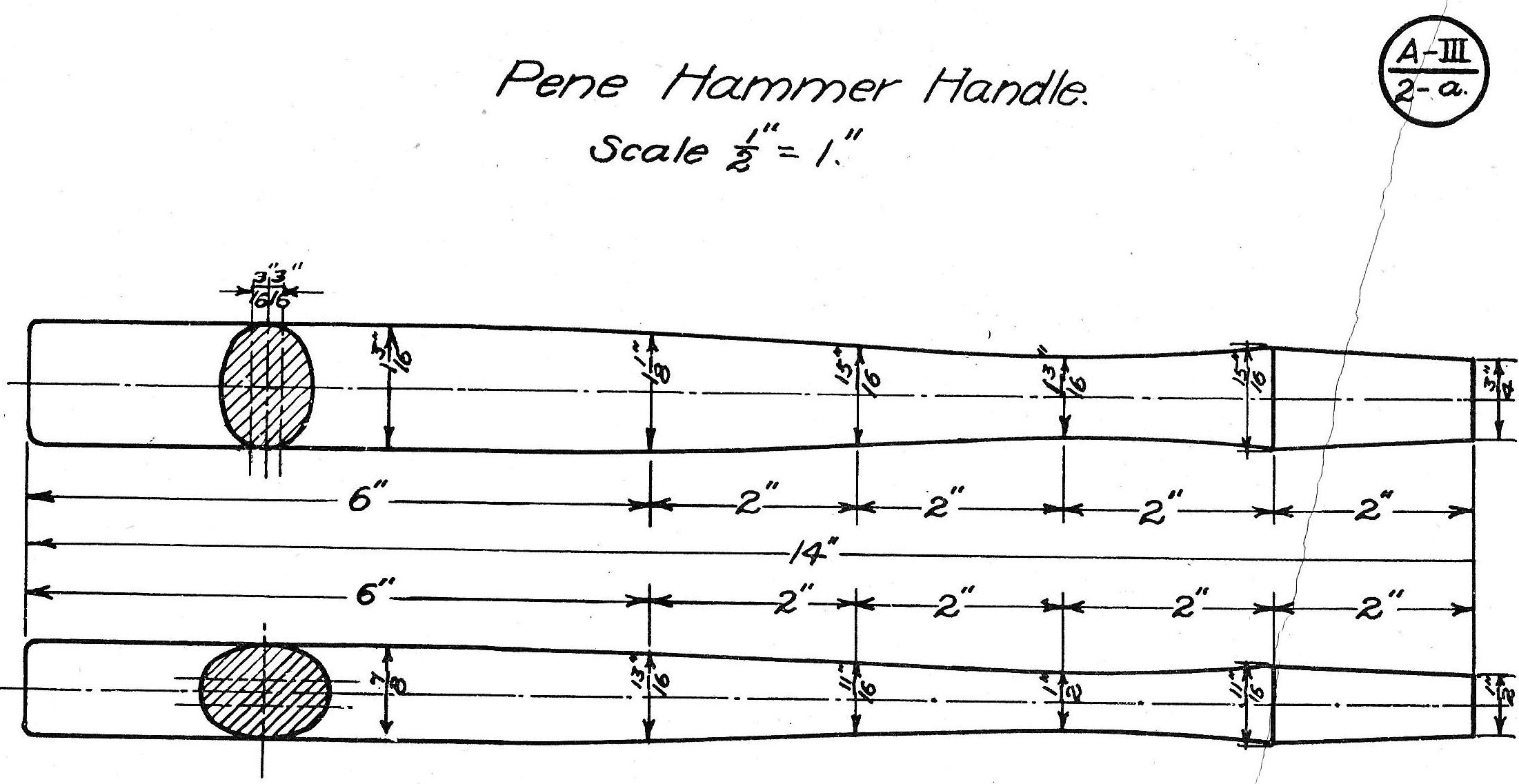

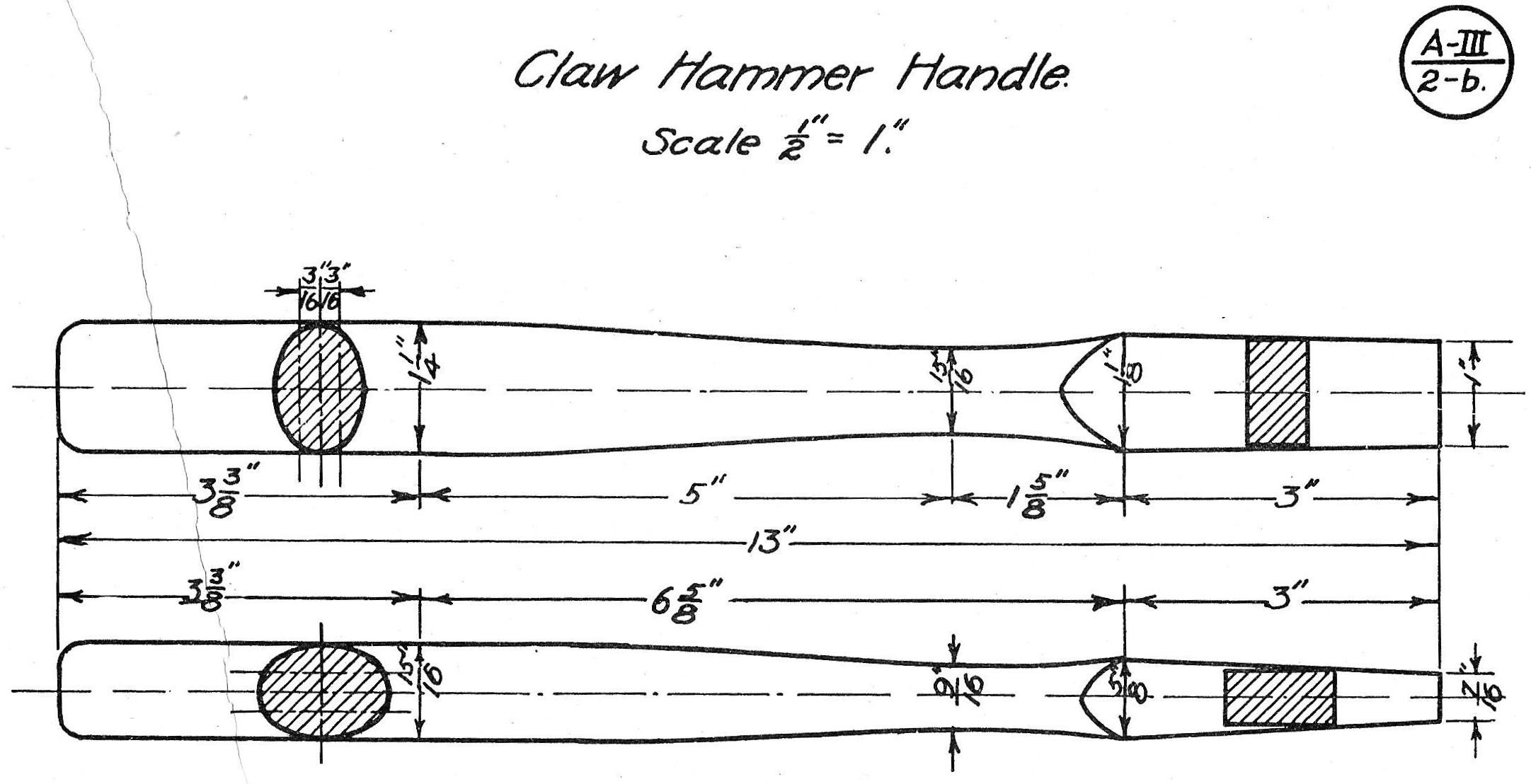

Oval work as a problem in turning will be found to be a very good one as well as interesting to the pupil. It brings in the principle of the oval as used in ordinary shop practice; (arcs from points on the major and minor axes). For thick heavy ovals the off-centering is very slight, while for long, thin ones the off-centering is greater. The measurements given on Plates A-III—l-a, b and A-III—2-a, b will give a good idea of approximate distances to be used.

While the tool operations are much the same as in other spindle turning there is one notable difference. The design must be worked out by eye, because of the nature of the work no caliper measurements can be made for depths of cuts.

To get the best results the stock of oval turning should be out square or slightly rectangular in cross- section and about 3” longer than the model to be made. The thickness of the stock should be about V3” greater than the major axis of the oval wanted.

The centers are located in the usual manner after which perpendicular lines are drawn from the sides, passing through the points of centers. From the ends of one of these, perpendicular lines are extended lengthwise of the stock (on opposite sides) meeting the corresponding perpendicular at the other end of the stock. These lines form the ridge of the oval. On the other perpendiculars, the points for off-centering are laid off, measuring the required distance on both sides of the center point.

With a 1/8” drill bore holes ¼” deep at each of the off-centering points as well as the original center. This will insure the lathe centers penetrating the stock at the proper point. The stock is then placed in the lathe, using two corresponding off-center points as centers.

With the lathe running at third speed, turn down the stock to the horizontal line forming the ridge of the oval, excepting for a distance of about 1¼” at the ends. The stock at the ends is necessary for the off-centering and, if cut away, will spoil the centering for the other side, especially at the live center end. The stock is then changed to the other off-center points and the second side is cut down to the line.

All measurements are then laid out and the design is cut, changing the stock in the lathe when necessary. Care should be taken that the sharp ridge left on the work forms a straight line the full length of the stock.

After the design has been finished, the stock is centered on the true center and a very thin cut is taken the full length of the object to remove the sharp corners. The model is then sandpapered while the lathe is running very slowly.

|

|