|

|

|

The Woodcrafter Page© 2004 - all rights reserved.

|

|

|

|

Here is the original article from the

May - June 1956 Deltagram

ROCKWELL MANUFACTURING COMPANY - A DELTACRAFT PULICATION

|

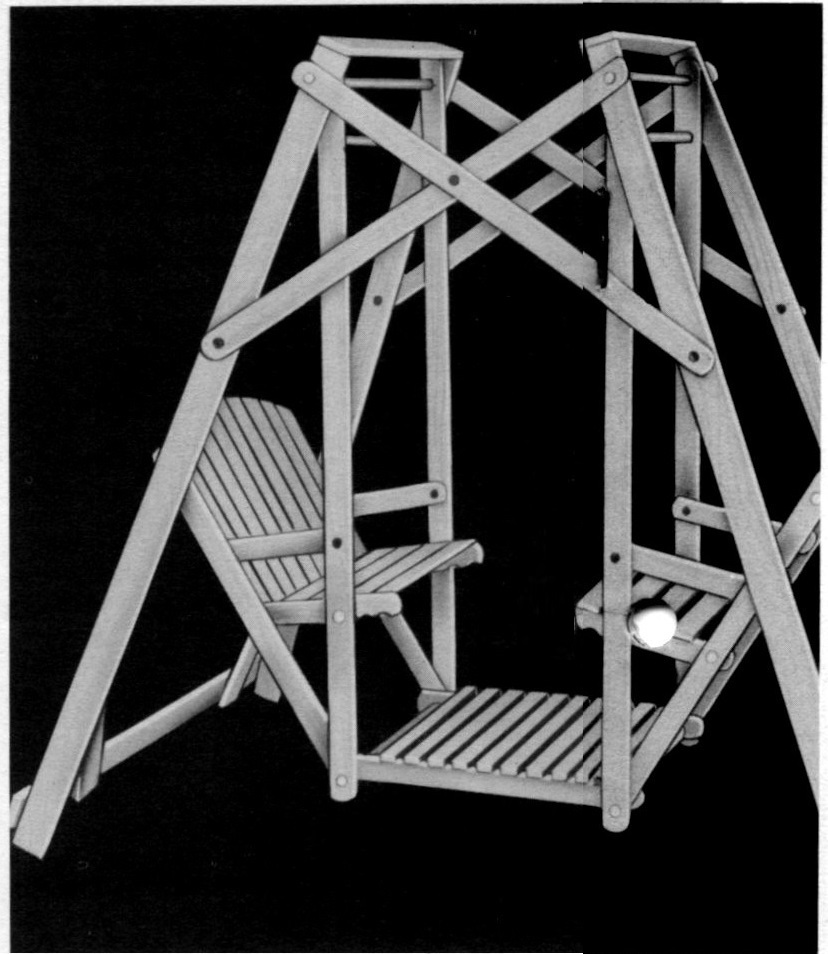

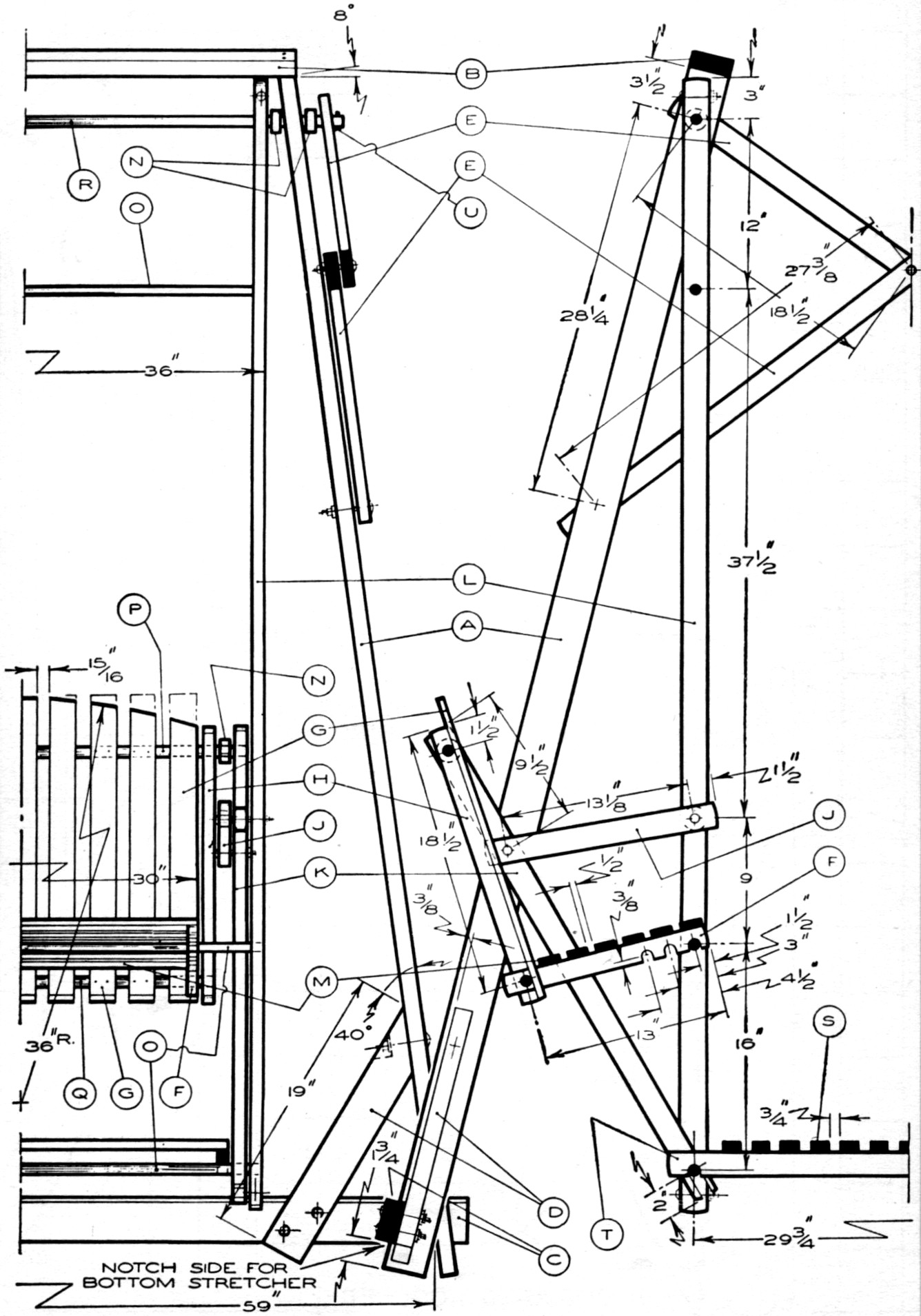

An Old Fashioned

L A W N S W I N G

|

Because of the many requests we have had from our readers for the Deltagram (no longer available) in which this lawn swing project appeared, we are again repeating it for our new readers as well as our many old friends.

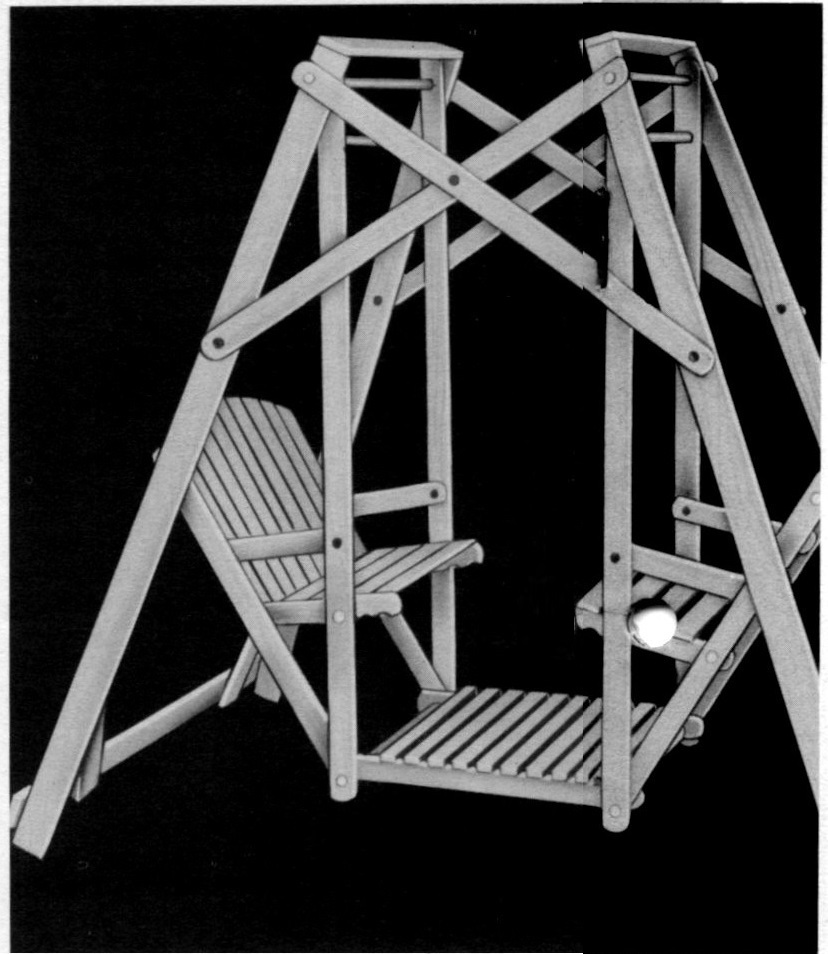

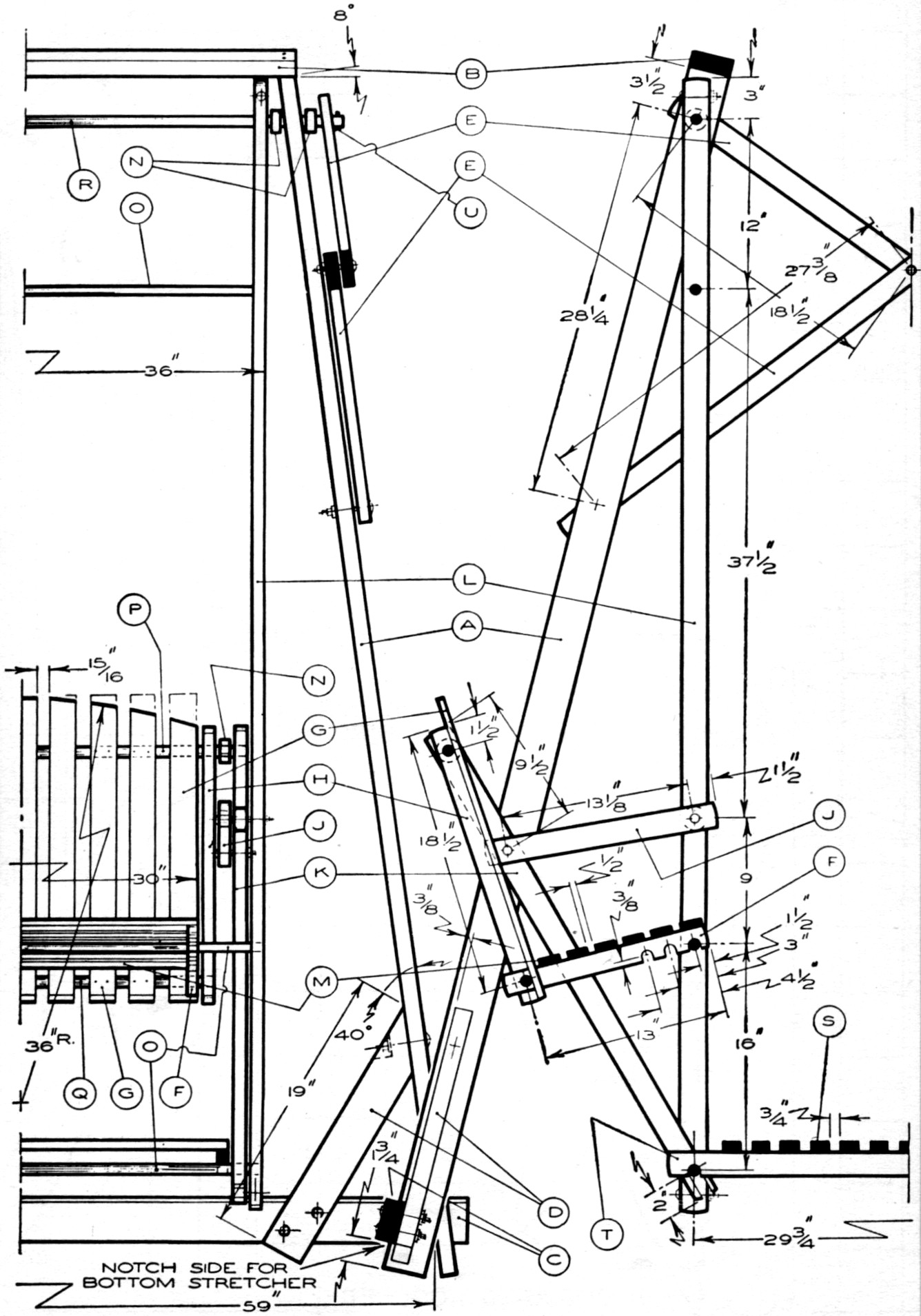

Here is a very practical lawn swing of the top suspension type which can be easily dismantled for Winter storage. No yard is complete without one especially if there are youngsters in the family.

It is made entirely of hard wood such as maple, birch, oak or ash and should be thoroughly protected from weathering with several coats of boiled oil (mixed—half oil and half turpentine) with plenty of drying time between coats. One of the new wood preservatives can be substituted for the boiled oil. It may then be finished with spar varnish or painted with two coats of a good grade of outside paint.

You will notice that the drawing carries only instructional dimensions. All part sizes are given in the bill of materials. Naturally, all sharp corners where one would be likely to grasp the swing should be well rounded, either with garnet paper or on the circular saw using the moulding cutterhead Cat. No. 265 and the Cat. No. 35-238 cutters. This should be done not only for comfort but as a precaution against slivers. |

|

|

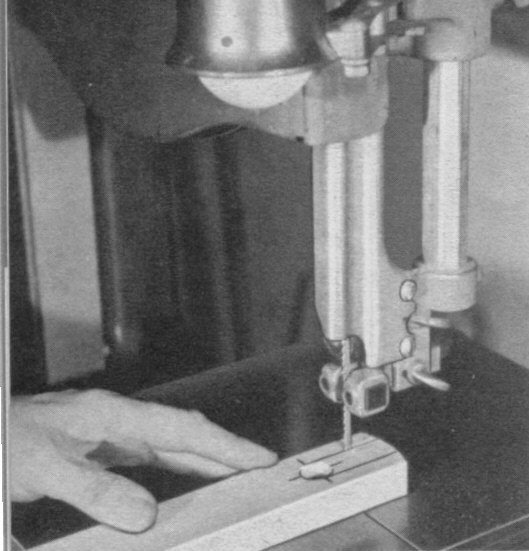

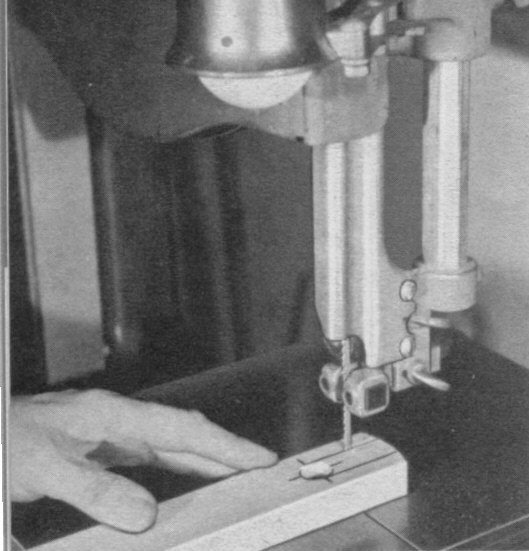

(Photo No. 1)

The fork in the seat back uprights is made by first drilling a ¾ hole

and then gutting out the slot on the band saw.

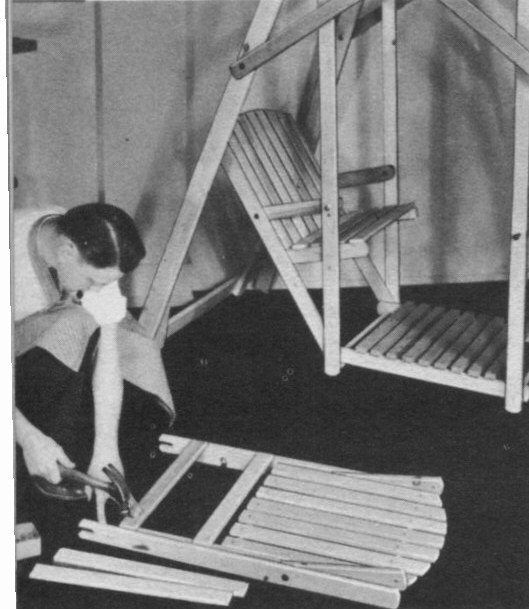

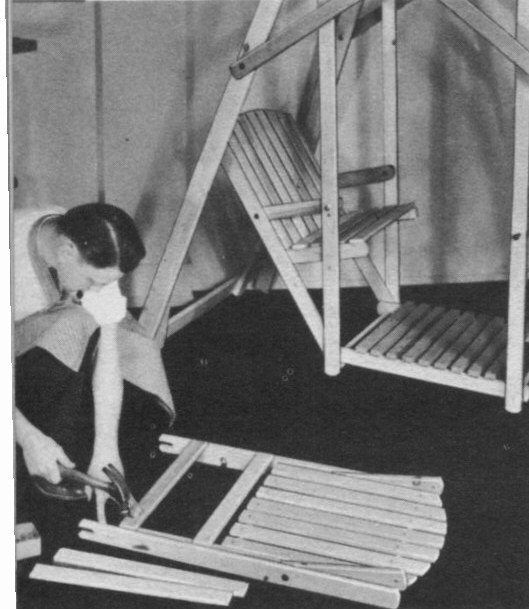

The above photo shows the seat being assembled

with lath nails.

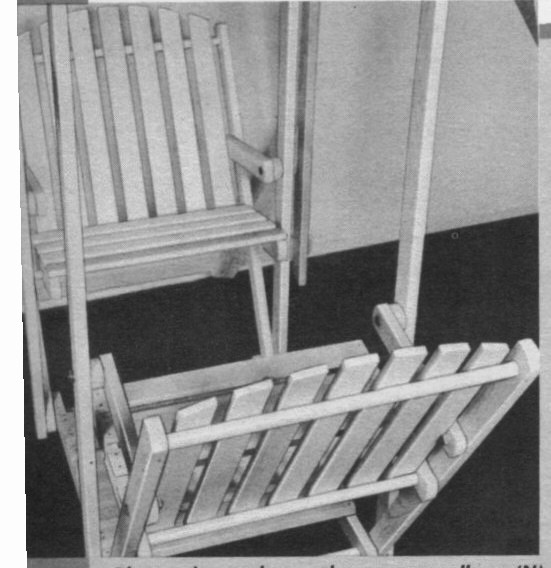

Photo above shows the spacer collars (N) used

between the seat swivel uprights and the seat

lock uprights.

|

BILL OF MATERIAL

| Item |

Req. |

Name |

Size |

| A |

4 |

Main frame side |

1-1/8 x 3 x 89 |

| C |

2 |

Main frame bottom stretcher |

1-1/8 x 3 x 63 |

| B |

2 |

Main frame top stretcher |

1-1/8 x 3 X 39½ |

| D |

4 |

Main frame support bracket |

1-1/8 x 3 x 19 |

| E |

4 |

Main frame cross arm |

¾ x 1¾ x 49-7/8 |

| N |

16 |

Spacer |

¾ x 1¾ x 1¾ |

| L |

4 |

Seat front upright |

¾ x 1¾ x 80½ |

| K |

4 |

Seat back upright |

¾ x 1¾ x 37½ |

| J |

4 |

Seat arm rest |

¾ x 1¾ x 16-1/8 |

| H |

4 |

Seat swivel upright |

¾ x 1¾ x 20 |

| F |

4 |

Seat swivel cleat |

¾ x 1¾ x 14½ |

| G |

18 |

Seat back slat |

½ x 2½ x 23¼ |

| M |

12 |

Seat slot |

½ x 1½ x 30 |

| T |

2 |

Floor slat support |

¾x1¾x33¾ |

| S |

13 |

Floor slat |

1-1/8 x 1-1/4 x 33 |

| O |

6 |

Dowel |

¾ dia. x 36 |

| P |

2 |

Dowel |

¾ dia. x 34½ |

| Q |

2 |

Dowel |

¾ dia. x 31½ |

| R |

2 |

Seat hanger rod (C.R.S.) |

5/8 diA. x 46 |

| R |

4 |

Cotter pin & 5/8 washer |

1/8 X 1-1/4 |

| U |

4 |

Carriage bolt |

5/16 dia. x 3¼ |

| |

8 |

Carriage bolt |

5/16 dia. x 2½

(fastening D) |

| |

2 |

Carriage bolt |

5/16 dia.x2 |

| |

4 |

Carriage bolt |

5/16 dia. x 2¾

(fastening E) |

| |

4 |

Carriage bolt |

5/16 dia.x2 |

| |

4 |

Carriage bolt |

5/16 dia.x2¾

(fastening J) |

| |

8 |

Carriage bolt

(anti-splitting of seat front upright) |

¼ dia. x 2-1/4 |

| |

16 |

Flat hd. wd. Screw |

No. l0 x 2½

(fastening B, C) |

| |

100 |

Lath nail |

(fastening G, M) |

| |

52 |

Flat hd. wd. screw |

No. 8 x 2¼

(fastening 5) |

|

|

Right-click here to download the drawing as an Adobe Acrobat (pdf) file.

* * * * Click on the drawings above to download a higher resolution picture. * * * *

*********** WARNING***********

Read my page on safety before building this item.

|